Plex Manufacturing Cloud is an ERP platform focused on manufacturing, unifying the management of every production phase in the cloud. It integrates functions of Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), and Quality Management Systems (QMS) in a single system, with additional modules for inventory, supply chain, accounting, sales, purchasing, and CRM. Each module shares a centralized database, ensuring real-time traceability of batches, materials, and plant operations. Its web architecture allows plant users, supervisors, and executives to access up-to-date data from any browser or mobile device, without relying on local infrastructure.

It stands out for its industry-specific approach, tailored to sectors such as aerospace, automotive, food and beverage, and life sciences, incorporating quality controls and compliance regulations (ISO, FDA, TS-16949, etc.). It also facilitates integration with plant equipment (PLC, SCADA) and IoT systems to collect real-time line data, driving decisions based on performance indicators (OEE), cycle time, and resource efficiency.

Features

Production Module

The production module acts as the operational core, enabling meticulous planning and real-time scheduling of work orders. Advanced algorithms and interactive dashboards optimize cycle times, facilitate batch tracking, and ensure traceability of every manufacturing stage—maximizing efficiency and meeting strict control standards.

Inventory and Supply Chain Management

Inventory management and supply chain coordination are enhanced through features that automatically update stock, control material movements, and trigger restocking alerts. Integration with external suppliers and other systems enables a continuous flow of information, reducing the risk of overstock or critical shortages and allowing dynamic adjustments to demand variations.

Quality Control

Quality control tools include automated processes that continuously monitor each production phase. Detailed reports and deviation analysis help identify inefficiencies or non-compliance, providing accurate data for corrective action and global performance improvement.

Finance

On the financial side, the ERP includes modules for invoicing, accounting, and cost analysis. This integration consolidates operational and financial data, supporting the creation of precise, customizable reports for strategic corporate decision-making.

Business Intelligence

The Business Intelligence component features interactive dashboards and advanced analytics. Real-time operational data extraction and analysis enable identification of key performance indicators (KPIs) and trend detection, promoting agile responses to market or internal process changes.

Integration and Customization

Integration and customization play a key role in the platform. Robust connectivity via APIs enables interoperability with external systems and the integration of emerging technologies like Internet of Things (IoT) devices, enhancing communication between the plant and administrative areas. Workflow configuration flexibility allows the solution to adapt to specific industry processes and optimize resources through the automation of repetitive tasks.

Maintenance Management and Equipment Traceability

The system also includes features for managing maintenance and equipment traceability. Tracking of preventive or corrective maintenance routines, along with historical data analysis, helps predict needs, minimize downtime, and extend the lifespan of critical machinery—essential in high-demand production environments.

Technical Specifications

Plex Manufacturing Cloud provides a unified environment that addresses both plant operations and corporate administration, ensuring full visibility from the shop floor to the administrative office. With its cloud-based architecture, the platform delivers automatic updates and reduces local infrastructure costs. Thanks to its configurable workflows, operations and IT teams can adapt processes without extensive development.

Architecture and Underlying Technology

The solution is built on a multitenant infrastructure in the cloud, hosted in redundant data centers to ensure high availability. The application layer uses standard web technologies (HTML5, JavaScript) along with native connectors that directly communicate with plant control systems (PLC, SCADA). The relational database engine guarantees real-time transactions, while REST APIs enable integration with IoT devices and external BI systems without compromising the system core.

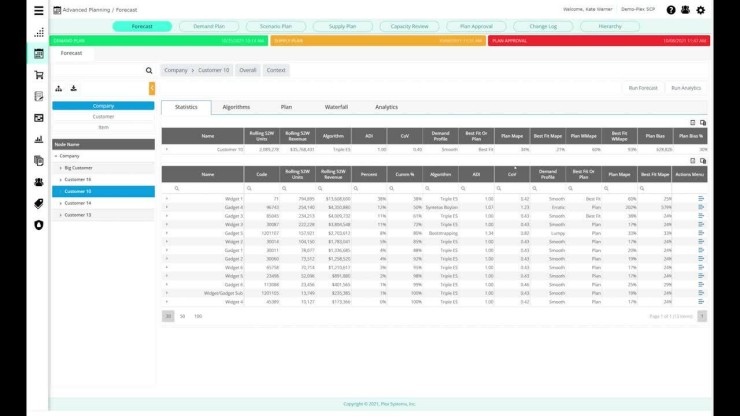

User Interface and Experience

The web interface features role-based dashboards, where each user sees key metrics (OEE, downtime, batch traceability) tailored to their role: machine operator, line supervisor, or plant manager. The dashboards provide interactive charts and automated alerts when critical deviations are detected (e.g., a batch out of specification). On mobile devices, Plex provides offline access to inspection data and work orders, automatically syncing once the connection is restored.

Implementation and Customization

Thanks to its cloud-native design, no local servers or hardware maintenance are required by the client. Deployment is guided by a wizard that configures company structures, locations, and manufacturing processes. To adapt forms, screens, and business rules, Plex includes low-code tools that allow business analysts to modify workflows without external consultants. Additionally, the Plex SQL Editor allows ad hoc query access to extract specific data, complementing standard reports.

Integration and Interoperability

Plex provides preconfigured connectors for transactional ERPs, advanced analytics solutions, and IoT systems monitoring plant machinery. Through its RESTful APIs, companies can link the platform to third-party applications such as predictive maintenance systems or computer vision tools. Thanks to native integration with PLCs, production data flows directly into the MES module, eliminating the need for manual scanning or duplicated data entry.

Security and Regulatory Compliance

The platform relies on TLS encryption in transit and AES at rest, ensuring sensitive data protection. Access control is based on granular roles and permissions, allowing field-level or transaction-level visibility and editing rights for each user. The platform includes a full audit trail of changes to records and documents, supporting compliance with standards such as FDA 21 CFR Part 11, ISO 9001, TS-16949, and food safety standards (HACCP).

Strengths and Weaknesses

| Strengths | Weaknesses |

|---|---|

| Comprehensive MES + ERP + QMS coverage: integrates plant execution, planning, and quality control, avoiding disconnected systems. | Steep learning curve: the broad functionality requires specialized training for users and admins during early stages. |

| Real-time visibility: plant, inventory, and quality data flow without delay, enabling fast operational and strategic decision-making. | Internet dependency: as a fully cloud-based platform, any network interruption or latency directly impacts plant operations. |

| Continuous updates: new features are rolled out without long downtimes; clients always use the latest version without complex migrations. | High cost for mid-sized businesses: the SaaS model and per-user/per-plant pricing may be higher than on-premise alternatives for small enterprises with limited budgets. |

| Adapted to regulated industries: supports quality standards (ISO, FDA, TS-16949), with full audits and batch traceability—ideal for food, pharma, and aerospace sectors. | Advanced customizations: despite low-code tools, highly specific processes or complex integrations may require external development and increase costs. |

| Native plant equipment integration: directly connects with PLCs, SCADA, and IoT—eliminating the need for intermediate systems to capture production data. | Feature-dense interface: plant operators may feel overwhelmed by the number of menus and functions; custom views and macros are needed to simplify UX. |

| Multi-site scalability: supports multiple plants or locations with real-time data consolidation, maintaining centralized control and global visibility. | Single-vendor dependency: being a cloud-native system from Plex/Rockwell, companies are tied to one provider’s roadmap and pricing policies. |

Software Classification

| Criterion | Classification |

|---|---|

| Licensing | Subscription / SaaS |

| Company Size | Mainly targeted at medium and large enterprises |

| Deployment Type | Cloud ERP: Deployed in a cloud environment to ensure global accessibility |

References

Official page of Plex, by Rockwell Automation: Plex Manufacturing Cloud

- Printer-friendly version

- Log in to post comments